BGW SERIES HIGH SPEED INTELLIGENT TABLET PORELESS FILM COATING MACHINE SUGAR COATING MACHINE

Suitable for food industry, chemical industry, Commodity industry, pharmaceutical industry and other packaging.(medicine tablet pill, candy)

- category : high efficiency film coating machine

- email : delia@snpkmachinery.com

- email : tony@snpkmachinery.com

- email : sales@snpkmachinery.com

- mobile : +86-15958748873

- mobile : +86-15868796452

- whatsapp : +86-15958748873

- whatsapp : +86-15868796452

Application:

The machine can be used for coating various tablets, pills and sweets with organic film, water-soluble film and sugar film, etc. And it has such characteristics as high efficiency, low energy consumption and small floor area, etc. And it can be widely used for coating various tablets, pills and sweets with organic film, water-soluble film and sugar film etc. In such fields as of pharmaceutical, food and biological products etc.

And it has such characteristics as good appearance in design ,high efficiency, low energy consumption and small floor area, etc.

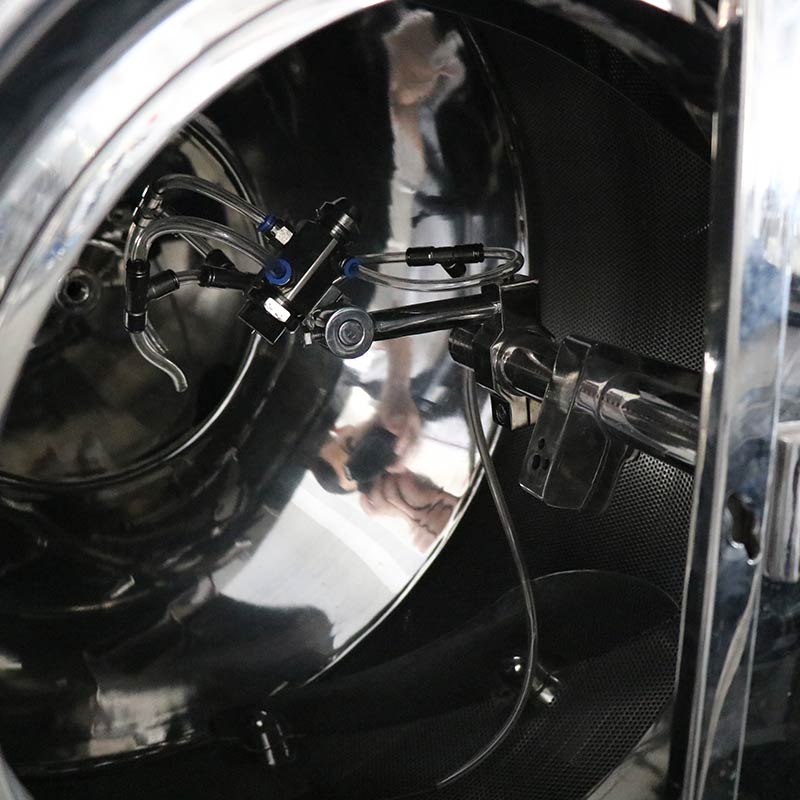

This machine is made of high-quality stainless steel elaborately and meets the The tablets make complicated and constant track movement with easy and smooth turning and frequent exchanging in the clean and closed rotational cylinder of the film coating machine. And it can automatically spray coating medium according to the process flow and reasonable process parameters. The hot air exhausted through the bottom of the tablets under the effect of air exhaust and negative pressure so as to make coating medium dry quickly on the surfaces of the tablets and form a firm, fine and close and smooth surface film.

Feature:

The drum of the main machine has a closed poreless structure and is equipped with a flow-guiding sheet. Tablets can make easy and smooth rotation without fragment and chipped edge in the drum due to mirror polishing of its wall and flow-guiding sheet, which greatly improves the yield. The perforated machine has a wide application, energy and auxiliary saving and easier to clean.

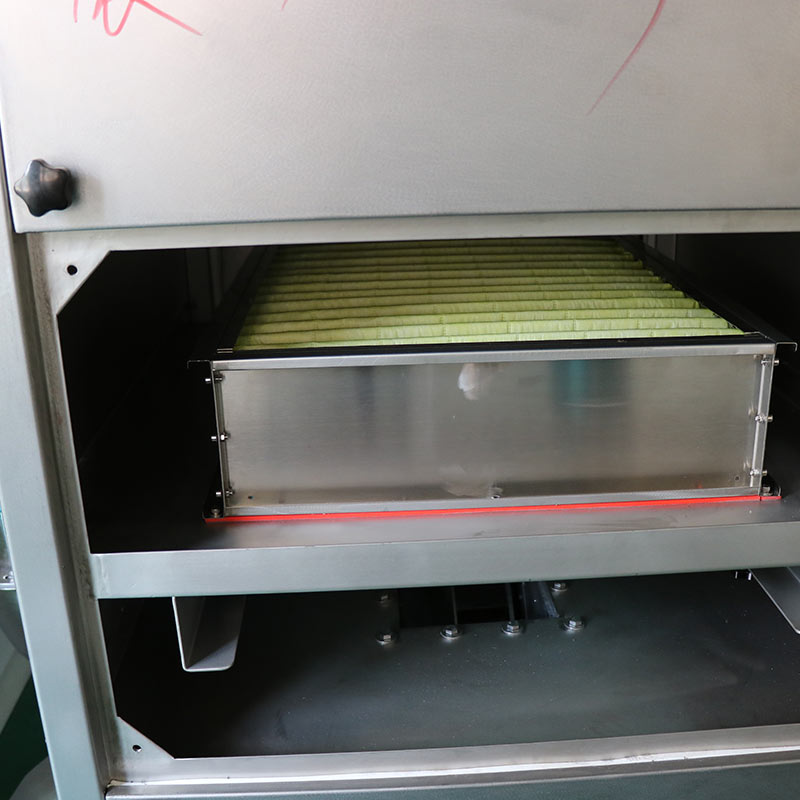

During air intake, three level filtration involving primary filtration, medium filtration and high filtration, can reach 100,000 level purification. During air exhaust, dust abatement can reach 99% by adopting a bag-type dust extractor.

A specially designed air source exchange system features exchange of hot air an cold air depending on the technological requirements, so to say, the fan propeller can be regarded as air inlet or air outlet. The propeller hole bore can meet the user's requirement from 0.6 to 3.00 mm, which is suitable for all types of tablet coating.

An eye detecting explosion-proof lamp is equipped in the drum so as to clearly view all material in run for the convenience of accurately control of coating technological in range.

|

|

|

|

|

|

Main Technial parameter:

| ITEM/MODEL | BGW300 | BGW150 | BGW80 | BGW40 | |

| Max. tablet volume | 300L | 150L | 80L | 40L | |

| Sugar coating drum speed | 0-13RPM | 0-16RPM | 0-19RPM | 0-21RPM | |

| Host machine power | 3KW | 2.2KW | 1.5KW | 0.75KW | |

| Diameter of coating drum | Φ1500mm | 1280mm | 1006mm | 825mm | |

| Exhaust cabinet motor power | 7.5kw | 5.5kw | 3kw | 2.2kw | |

| Exhaust air flow | 10000m³/h | 7420m³/h | 5260m³/h | 3520m³/h | |

| Hot air cabinet motor power | 2.2kw | 1.5kw | 1.1kw | 0.75kw | |

| heater air flow | 3520m³/h | 2350m³/h | 1680m³/h | 1280m³/h | |

| Host machine weight | 1200kg | 1000kg | 800kg | 550kg | |

| Clean air | Pressure | ≥0.4Mpa | ≥0.4Mpa | ≥0.4Mpa | ≥0.4Mpa |

| Air comsumption | 1.1m³/h | 0.7m³/h | 0.35m³/h | 0.15m³/h | |