BG SERIES HIGH EFFICIENCY AUTOMATIC PHARMACEUTICAL TABLET PILL SUGAR FILM COATING MACHINE

Suitable for food industry, chemical industry, Commodity industry, pharmaceutical industry and other packaging.(medicine tablet pill, candy)

- category : high efficiency film coating machine

- email : delia@snpkmachinery.com

- email : tony@snpkmachinery.com

- email : sales@snpkmachinery.com

- mobile : +86-15958748873

- mobile : +86-15868796452

- whatsapp : +86-15958748873

- whatsapp : +86-15868796452

Application:

The machine can be used for coating various tablets, pills and sweets with organic film, water-soluble film and sugar film, etc. And it has such characteristics as high efficiency, low energy consumption and small floor area, etc. And it can be widely used for coating various tablets, pills and sweets with organic film, water-soluble film and sugar film etc. In such fields as of pharmaceutical, food and biological products etc.

And it has such characteristics as good appearance in design ,high efficiency, low energy consumption and small floor area, etc.

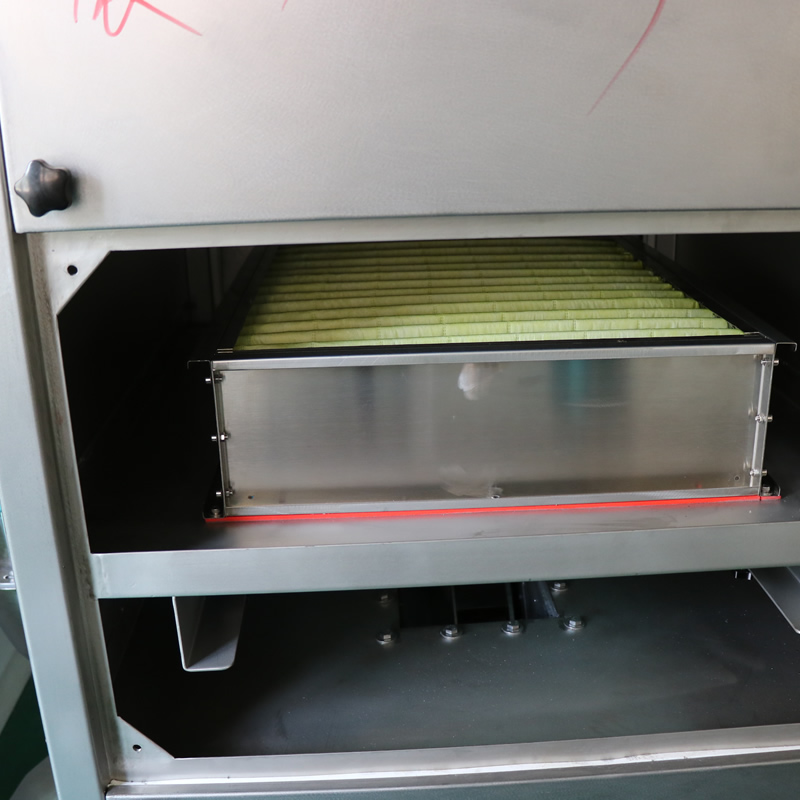

This machine is made of high-quality stainless steel elaborately and meets the The tablets make complicated and constant track movement with easy and smooth turning and frequent exchanging in the clean and closed rotational cylinder of the film coating machine. And it can automatically spray coating medium according to the process flow and reasonable process parameters. The hot air exhausted through the bottom of the tablets under the effect of air exhaust and negative pressure so as to make coating medium dry quickly on the surfaces of the tablets and form a firm, fine and close and smooth surface film.

Feature:

With PLC module, all operations such as hot air temperature setting and control, revolutions of the drum adjustment, automatic control and display of negative pressure etc can be in run by pushing the touch key on the computer-controlled panel fully sealed with slight touch film interface.

The machine is free to clean, with such characteristics as reliable and stable performance.

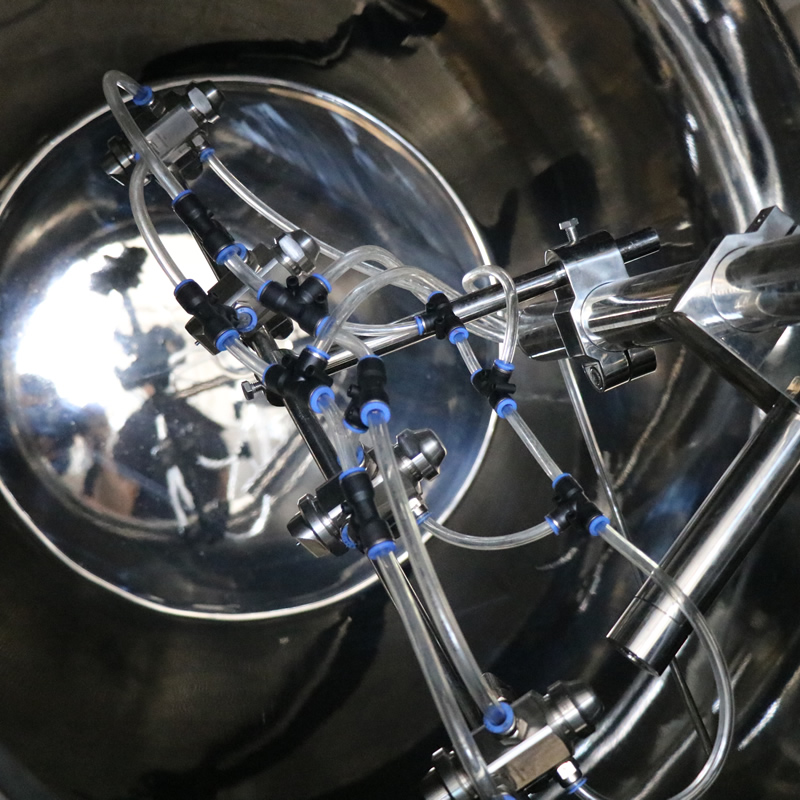

The streamline guiding-type mixer drives tablets to make easy and smooth rotation without fragment and chipped edge, which improves the yield.

The guiding sheet has a narrow surface, to which no dressing can be stuck, economization on dressing and improving the quality of finished products.

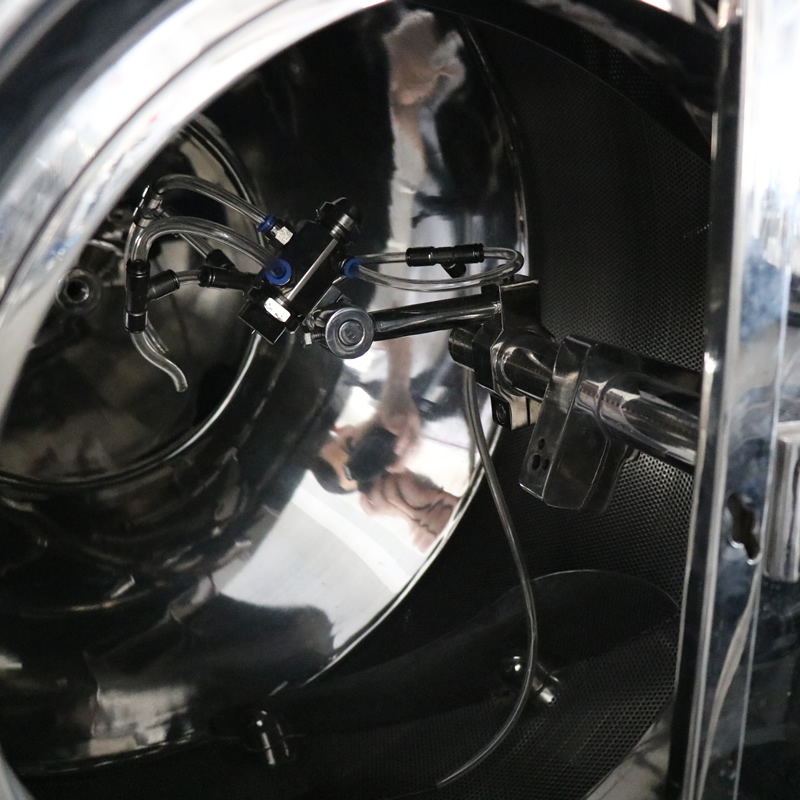

The constant-pressure variable crawler pump features the revolution radius of the roller subject to pressure, automatic control of output syrup amounts and sprayed syrup amounts, stabilization of atomization, simplify of spraying system, economization on dressing, easy to fully clean.

The specially designed imported s pray gun features east to operate and control technological requirements, uniform density and particle size, uniform atomization and large spray area, practical to adjust flow, free leakage and blockage, angle and sector.

|

|

|

|

|

|

Main Technial parameter

| ITEM/MODEL | BG600 | BG400 | BG150 | BG80 | BG40 | BG10 | BG20H | BG5H | |

| Max. tablet volume | 600L | 400L | 150L | 80L | 40L | 10L | 20L | 5L | |

| Sugar coating drum speed | 0-12RPM | 0-13RPM | 0-16RPM | 0-19RPM | 0-21RPM | 0-25RPM | 0-25RPM | 0-30RPM | |

| Host machine power | 5.5KW | 3KW | 2.2KW | 1.5KW | 1.1KW | 0.55KW | 0.75KW | 0.37KW | |

| Diameter of coating drum | Φ1580mm | Φ1580mm | Φ1200mm | Φ930mm | Φ750mm | Φ500mm | Φ680mm | Φ480mm | |

| Exhaust cabinet motor power | 11kw | 7.5kw | 5.5kw | 3kw | 2.2kw | 0.75kw | 2.2kw | 1.1kw | |

| Exhaust air flow | 15450m³/h | 10000m³/h | 7420m³/h | 5270m³/h | 3500m³/h | 1300m³/h | 3500m³/h | 2500m³/h | |

| Hot air cabinet motor power | 5.5KW | 3KW | 1.5kw | 1.1kw | 0.75kw | 0.37kw | 0.75KW | 0.25kw | |

| heater air flow | 7420m³/h | 5200m³/h | 2360m³/h | 1670m³/h | 1280m³/h | 820m³/h | 1200m³/h | 500m³/h | |

| Host machine weight | 2800kg | 1560kg | 1020kg | 685kg | 500kg | 200kg | 750kg | 625kg | |

| Clean air | Pressure | ≥0.4Mpa | ≥0.4Mpa | ≥0.4Mpa | ≥0.4Mpa | ≥0.4Mpa | ≥0.4Mpa | ≥0.4Mpa | ≥0.4Mpa |

| Air comsumption | 2m³/min | 1.5m³/min | 1m³/min | 0.4m³/min | 0.4m³/min | 0.3m³/min | 0.6m³/min | 0.6m³/min | |

| Host machine dimension | 2000*2277*2660mm | 2000*1670*2660mm | 1570*1260*2250mm | 1210*1000*1900mm | 1000*800*1900mm | 900*620*1800mm | 1050*960*1800mm | 1250*900*1700mm | |

| Hot air cabinet dimension | 1600*1100*2350mm | 1000*900*2300mm | 900*800*2050mm | 900*800*2050mm | 900*800*2050mm | 800*650*1600mm | 1050*960*1800mm | ||

| Air exhaust cabinet dimension | 10050*1000*2470mm | 1050*1050*2300mm | 950*950*2245mm | 900*820*2130mm | 820*720*1750mm | 800*650*1600mm | 659*600&1000mm | ||