SN-ZS5260 AUTOMATIC COSMETICS CARD BLISTER PACKING MACHINE FOR LIP GLOSS MENTHOLATUM TOOTHBRUSH

Suitable for food industry, chemical industry, Commodity industry, pharmaceutical industry and other packaging.(CAPSULES ,TABLETS, MILK PIECES, CANDY,LIQUID CHEESE,BATTERY,bearing,COSMETICS, LIP GLOSS ,MENTHOLATUM ,TOOTHBRUSH)

- category : blister packing machine

- email : delia@snpkmachinery.com

- email : tony@snpkmachinery.com

- email : sales@snpkmachinery.com

- mobile : +86-15958748873

- mobile : +86-15868796452

- whatsapp : +86-15958748873

- whatsapp : +86-15868796452

Application:

It is suit for daily use, stationery, minor hardware, cosmetics, medicines, as well as battery, toothbrush, pens, glues, plug base, bearing, etc. to improve the grade of the finished products.

Feature:

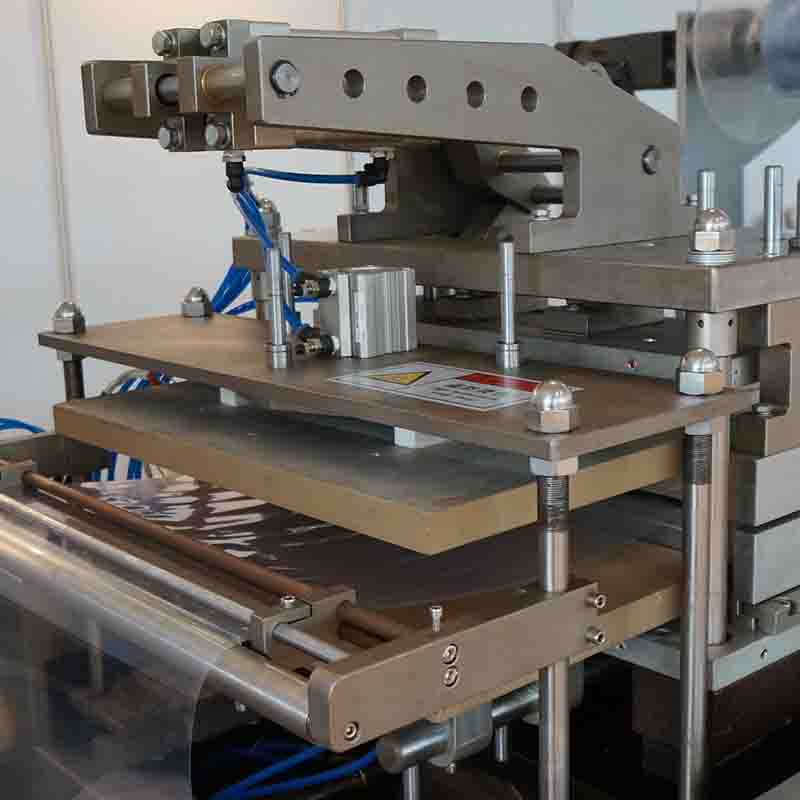

It is an ALL in one automatic card blister packaging system (Form/ Cut blister form/Product feed/Card supply//Seal) designed to meet a wide variety of packaging applications with high efficiency at economical price.

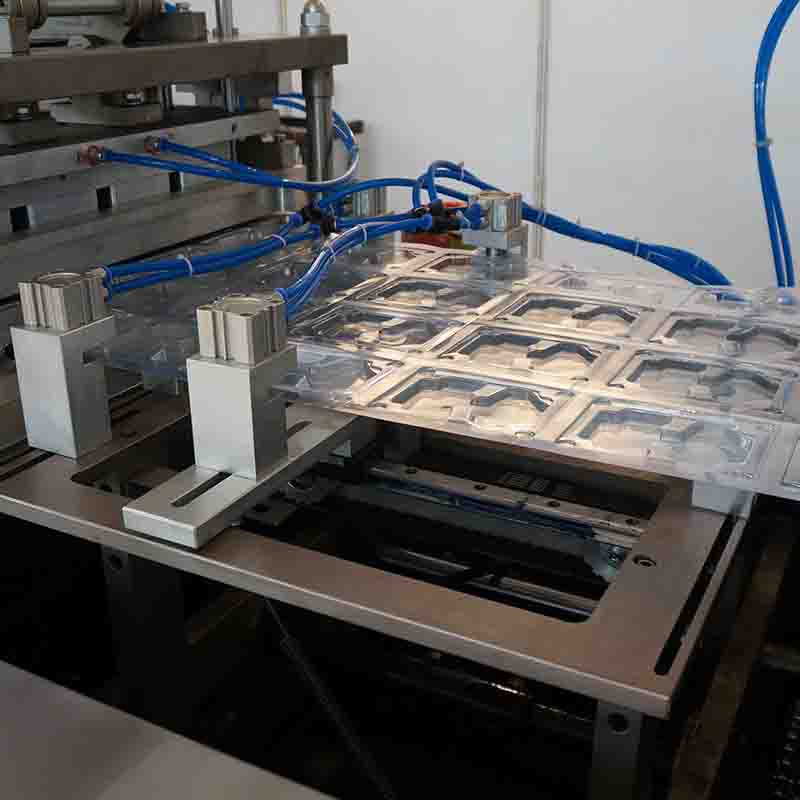

Just in time blister forming eliminates pre-form blister inventory.The plastic forms are placed in a die which is 28(or 32) pieces consisted a crawler-type circle. Thus the machine can perform fast and steadily.

Each card is fixed by accurate alignment dowels.

On the sealing station, we use our unique type to make each pack sealed 2 times. The sealing result will be much firmer than the type of sealing 1 time.

The blister packing machine has installed the clutch to shut down the machine when any fault. So the machine never muddle up in production.

|

|

|

|

|

|

|

|

| Speed | 15-20Strokes/Min. |

| Packing Material Size(PVC) | 520×(0.2-0.50)mm |

| Max.diameter 500mm,Inside diameter 75mm | |

| Cardboard Spec. | 220×620mm 200~700g |

| Max.Forming size | Length500×Width180×Depth35mm |

| Travel range | 40~180mm |

| Compressed air | 0.5-0.8Mpa (Dry,no oil,clean air supply) |

| Air consumption | 0.3(m3 /min.) |

| Vacuum supply | Pumping rate>40 m3 /min. |

| Total water consumption | 50L/H(For cooling mold ) |

| Chiller 1.3Kw | |

| Power supply | 380V 50Hz 3Phase 5wires |

| Total power | 16.5Kw |

| Setting environment | Relative humidity45~65%,Temperature<30℃ |

| Machine size | L6300×W1300×H1750mm |

| Machine weight | 4200Kg |