SN-DPP260 HIGH SPEED BLISTER PACKING MACHINE FOR TABLETS PILL

Suitable for food industry, chemical industry, Commodity industry, pharmaceutical industry and other packaging.(CAPSULES ,TABLETS, MILK PIECES, CANDY,LIQUID CHEESE,BATTERY,bearing,COSMETICS, LIP GLOSS ,MENTHOLATUM ,TOOTHBRUSH)

- category : blister packing machine

- email : delia@snpkmachinery.com

- email : tony@snpkmachinery.com

- email : sales@snpkmachinery.com

- mobile : +86-15958748873

- mobile : +86-15868796452

- whatsapp : +86-15958748873

- whatsapp : +86-15868796452

Application:

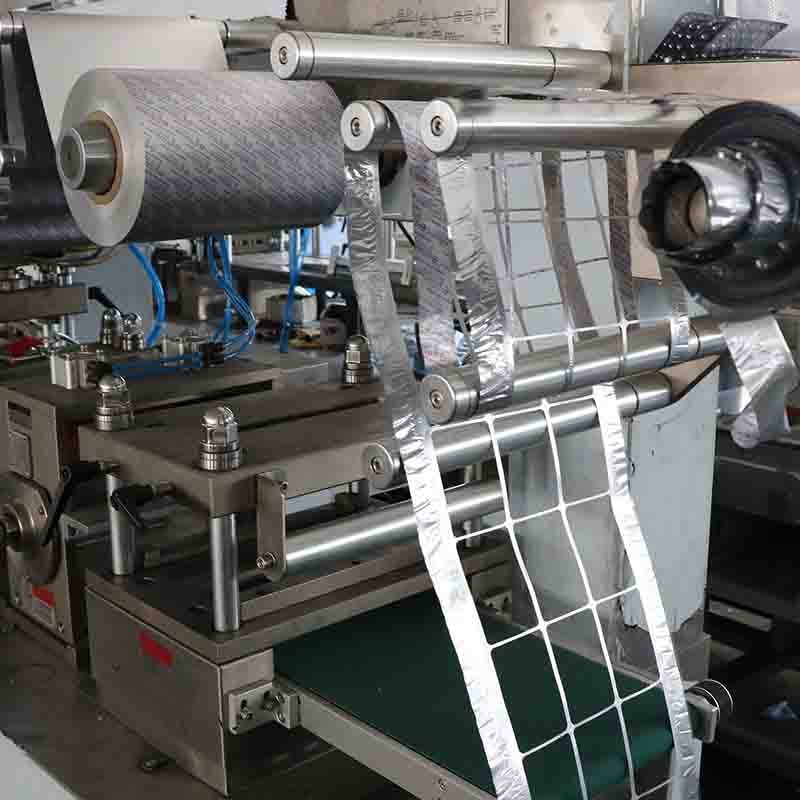

DPP260 blister packing machine is a machine adopts in the lead position of quality, good capability, all-round function, good reliability and high productivity. It adopts auto-controlling technology and uses new material, new craft, and new technology to make the structure more reasonable.

DPP260 combines the advantages of good forming of flat pattern packing machine and high speed of roller pattern machine. The forming could be done in low speed through reasonable speed matching. And the sealing station, compressing station and punching station could achieve a speed of 120 cutting per minute. High speed is with perfect function

This series machine is at high precise and the latest roller and plate type blister packing machine, developed by our company. It applies to pharmaceutical industry, food industry, medical appliance and electronically area. It is suitable for packing capsules, tablets, milk pieces, candy, electronically element and similar material, with sealing packing in aluminum PVC, paper PVC Blister Package.

Feature:

1. This machine adopts the latest model of high-power transmission, the row chain drive the transmission shaft, which eliminates the other gear transmission error and noise.

2. Electrical adopts the imported control systems, which can be customizing by the user. Equipped with the short shot up leakage device, missing particle detection and removed device (Omron Sensor). Adopts imported inverter.

3. This machine adopts optoelectronic system: PVC,PTP,tropical aluminum packaging and automatic feeding,waste selvage automatic material receiving device, which ensure the long-distance multi-site synchronization stability.

4. This machine adopts sub-portfolio structure: PVC informing,feeding,hot sealing; Tropical aluminum cold forming,hot sealing,blanking

5. This machine can be equipped with reprovision photoelectric detection and corrected device, equipped with imported stepper motor, photo printing and packaging, which will optimize the grades of packaging.

6. Application: capsule, tablets, pill, injection and other medicine and food, electronic components blister sealed packaging.

|

|

|

|

|

|

| Speed | 60-150cuts/min | |

| Scope | 20-250 mm | |

| Max. Forming Area | 180×250mm | |

| Max.Depth | 12mm | |

| Power and E-Consumption | Three Phase 380V 50HZ(220V 60HZ) | |

| 14KW | ||

| Air Consumption | Air pressure 0.5-0.7Mpa | |

| Air consumption:0.2m³/min | ||

| Cooling Water Consumption | Water pressure:0.1-0.25Mpa | |

| Water consumption:0.01-0.02m³/min | ||

| Packing | PVC | (0.25-0.35)×260 |

| Material | PTP | 0.02X260mm |

| PVC roll diameter | <φ400mm | |

| PTP roll diameter | <φ250mm | |

| PVC & PTP core diameter | φ70~76mm | |

| Weight | 2500Kg | |