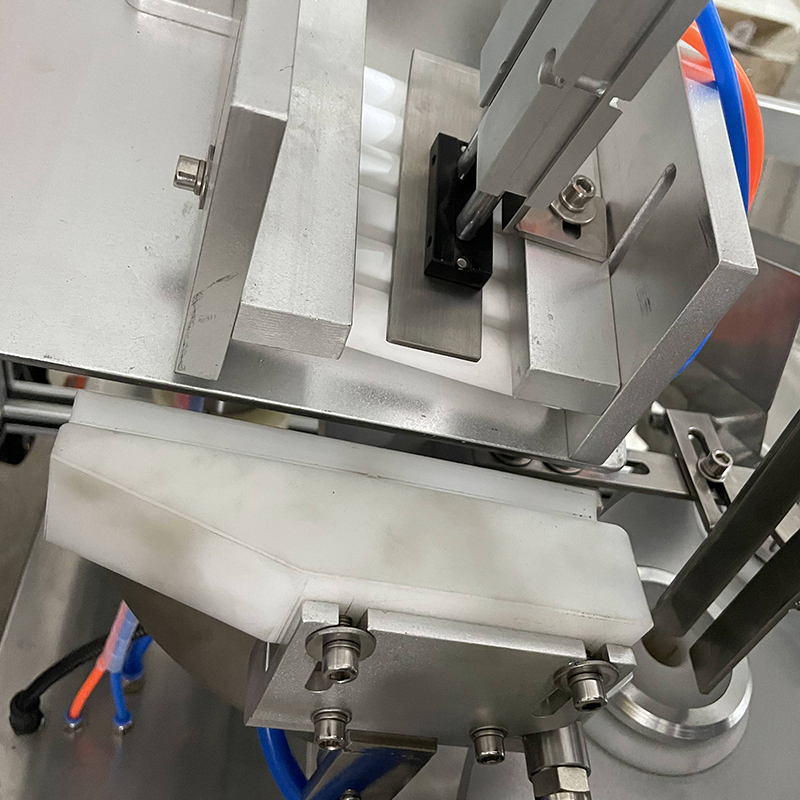

SN-TB60A AUTOMATIC ALUMINUM TUBE FILLING AND SEALING MACHINE FOR OINTMENT

Suitable for food industry, chemical industry, Commodity industry, pharmaceutical industry and other packaging.( COSMETICS,toothpaste,ketchup,hand cream, face cream,Lip cream,pomade,OINTMENT)

- category : Tube Filling and Sealing Machine

- email : delia@snpkmachinery.com

- email : tony@snpkmachinery.com

- email : sales@snpkmachinery.com

- mobile : +86-15958748873

- mobile : +86-15868796452

- whatsapp : +86-15958748873

- whatsapp : +86-15868796452

Feature

■ This Product have 9 stations, can choose different station and equip corresponding manipulator to meet different type of sealing requirement for plastic tube, laminated tubes, It is a multi-purpose machine.

■ Tube feeding, eye marking,material filling, sealing, batch number printing, finished products discharging can be performed automatically (the whole procedure).

■ Tube storage can through motor to adjust up-down height as per different tube length. And can With external reversal feeding system, makes tube charging more convenient and tidy.

■ The mechanical linkage photo sensor precision tolerance is less than 0.2mm. reduce the chromatic aberration scope between tube and eye mark.

■ Light, electric, pneumatic integrative control, No tube, no filling. Lower pressure, auto display (alarm); The machine stop automatically if tube error or open the safety door.

■ Double-layer jacket instant heater with inside air heating, it won’t damage the pattern outer wall of tube and achieves firm and beautiful sealing effect.

|

|

|

|

|

|

|

|

|

|

| Applicable | toplastic composite tubes and aluminum plastic conposite tubes |

| Operation speed | Max. 60/min |

| Filling volume | 5-250ml |

| Filling precision | ≤±1% |

| Suitable tube length | 50-210mm |

| Suitable tube diameter | 13-50mm |

| Dimension | 1800*850*1980mm |

| Weight | 850kg |

| Standard configuration | obiquely hanging type automatic lining-up tube feeding storehouse |

| Optional | externally allocated refrigerator |

| Optional | jacket and barrel heat presevation device |

| Optional | blending device inside the barrel |

| Optional | automatically controlled material feeding device |

| Optional |

finished tube conveyor |