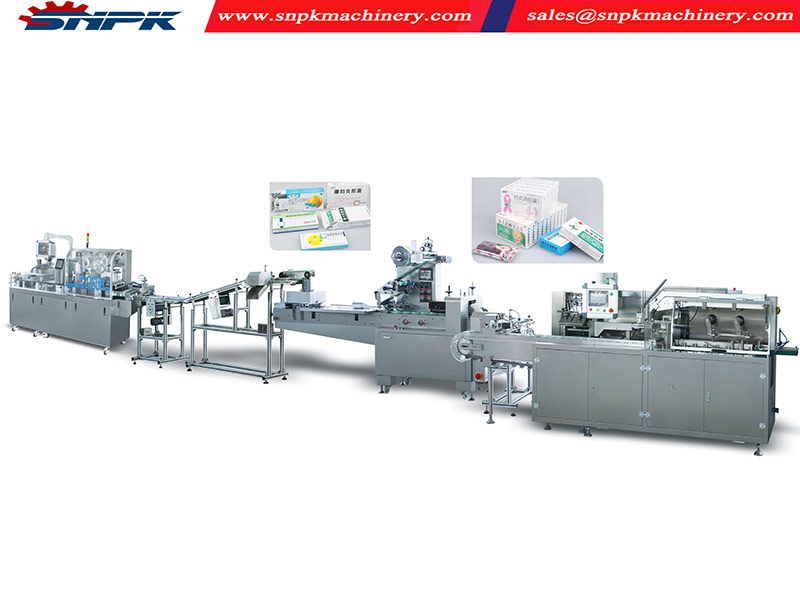

SN-DHP400 BLISTER CARTONER PACKING PRODUCTION LINE

suitable for bottle,vial,oral solution,COSMETICS,syrup

- category : Medicine packing automatic production line

- email : delia@snpkmachinery.com

- email : tony@snpkmachinery.com

- email : sales@snpkmachinery.com

- mobile : +86-15958748873

- mobile : +86-15868796452

- whatsapp : +86-15958748873

- whatsapp : +86-15868796452

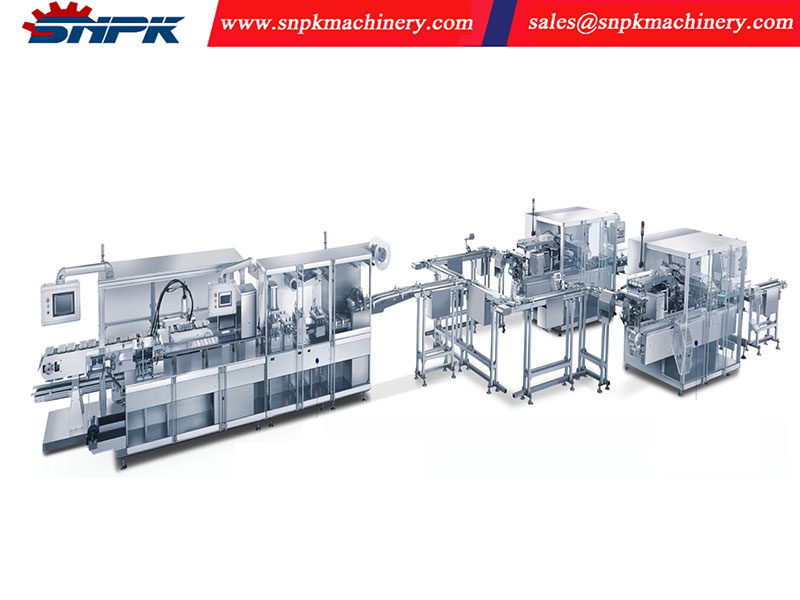

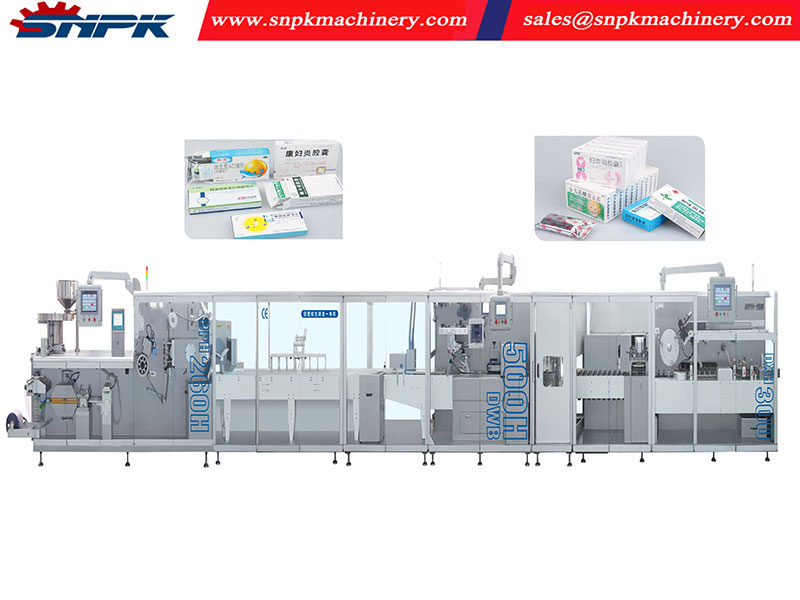

Capacity of DHP400 Full Servo Superfast Blister-cartoner Link machine up to 400 blister/min and 300 carton/min. Transit by our company own R&D IBR24 parallel-type robot hand s trace& Transfer System to transfer the blisters on grid conveyor belt into parallel cartoner stock bin conveyor. This type of transfer not only shorten production line length, and max upgrade OEE max protect the stability. And it combines multichannel grid conveyor belt, can achieve mult-blisters overlay Compare with the original blister flat conveyor belt transfer to magazine then servo feed into stock bin, this linkage way production is doubled, also is a milestone span of pharmaceutical packaging way. This packaging way will certainly become a development trend of pharmaceutical industrial machinery. Feature of differ from other models is integrated every advantage of existing highspeed blister packing machine and cartoning machine, highlights of this machine is in the meantime of high speed prostion to protect fast mould replace and cleaning. Original creative(1-5 )blisters carton packing new mode, can switch 1-5 blisters carton packing in one minute. Leaflet folding device can achieve capacity 300PCS/Min for A4 paper. This link machine can achieve isolate roduction between inner and outer packing room. Break through this model machine international peers at present grid conveyor belt transfer inner and outer packing room is interconnected, creates a pharmaceutical packaging safety risks. Adopts balcony structure design, driving device located at back, easy for cleaning, accord with GMP requirements.

Main Features:

* Simple structure in linear type ,easy in installation and maintation.

* Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

* High pressure double crank to control the die opening and closing.

* Running in a high automatization and intellectualization,no pollution

* Apply a linker to connect with the flow packing,check weighter,bundering and so on

|

|

|

|

|

|

Main technial parameter:

| Pouching frequenty | 40-160times/min |

| Max.forming size | 245*110mm |

| Max forming depth | 12mm |

| stroke adjusting | 150-250mm |

| width and thickness of PVC and PTP | PVC:260*0.15-0.3mm |

| PTP:260*0.02-0.03mm | |

| size of standard blister | 80*57mm |

| power supply | 380V 50HZ 12KW |

| Overall dimension | 4350*1070*2200mm |

| Weight | 3200kg |

| pillow packing machine | |

| production capacity | 60-300bags/min |

| packing size | L:60-200mm,W:35-150mm,H:5-30mm |

| Machine dimension | 3750*1280*1800mm |

| Weight | 2500kg |

| working pressure | ≥0.6mpa |

| air consumption | 20m³/h |

| power supply | 380V 50HZ 7.5KW |

| cartoning machine | |

| Encasing speed | 80-300boxes/min |

| quality box requirement | 250-350g/㎡ |

| Dimension rang(L*W*H) | (70-200)*(35-85)/(70-120)*(14-70)mm |

| specification paper requirement | 50-70g/㎡ |

| unfolded leaflet specification | (80-260)*(90-190)mm |

| folded leaflet specification | 1-4(fold) |

| power supply | 380V 50HZ 5KW |

| Machine dimension | 4450*1500*1750mm |

| weight | 4200kg |