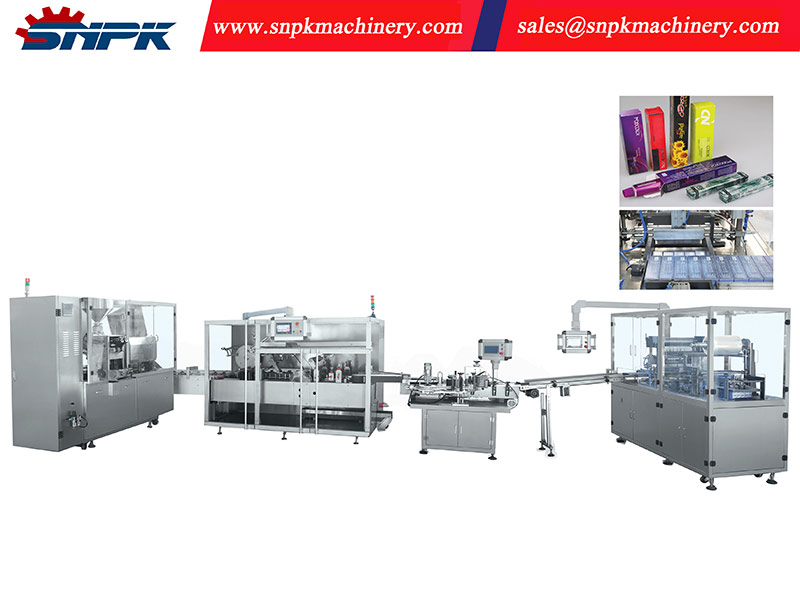

SN-TB2000 AUTOMATIC TUBE FILLING CARTONING AND SHRINK PACKING LINE

Suitable for food industry, chemical industry, Commodity industry, pharmaceutical industry and other packaging.(toothpaste, hardware,bearing,drug,COSMETICS,hand cream, face cream,medicine tablets,bread,cake)

- category : Automatic carton packing line

- email : delia@snpkmachinery.com

- email : tony@snpkmachinery.com

- email : sales@snpkmachinery.com

- mobile : +86-15958748873

- mobile : +86-15868796452

- whatsapp : +86-15958748873

- whatsapp : +86-15868796452

The Production line is a high technical integrative equipment which successfully developed and designed on the base of many years experiences of developing autom-atization machine ,it's adopted with PLC, human-machine interface operation panel, and it can automatic execute tube supply, photoelectrical register, filling and sealing batch number printing, finished product output, instruction Paper folding, box open, object feeding into box, batch number (including manufacture date) print, and boxes edge sealing and several boxs shrink packing.

Technical Charcters

■ High grade operation screen with LCD display and PLC control, easy operation and more humanization by stepless speed adjust, parameter set, output count, pressure index and failure display.

■ Automatically executing tube supply,photocell register, inert gas filling, material filling and sealing, batch number printing, final products output.

■ High prevision photocell register; that reduces the chromatic aberration scope.

■ Adjustment parts external in position, position digital display, convenient and accurate adjust (suitable for variable products producing).

■ Mechanical, photoecectrical, electric, pneumatic integrative controlling, reaches no tube no filing function: warning if tube error positioned or pressure too lowz it will automatic stop while open the protective door.

|

|

|

|

|

|

| Operation speed | Max. 80/min |

| Filling volume | 5-250ml |

| Filling precision | ≤±1% |

| Suitable tube length | 50-210mm |

| Suitable tube diameter | 13-50mm |

| Dimension | 2200*1200*2080mm |

| Weight | 1200kg |

| Standard configuration | obiquely hanging type automatic lining-up tube feeding storehouse |

| Standard configuration | saddle folding and sealing device,which can realize |

| Optional | Three-side and four side folding through adjustment |

| Optional | jacket and barrel heat presevation device |

| Optional | blending device inside the barrel |

| Optional | automatically controlled material feeding device |

| Optional | finished tube conveyor |

Cartoning machine

| Production Capacity | <120 boxes/min |

| Size Of Box(LX WXH) | (50-190) X (25-120) X(12-70)mm |

| Specification Of Box | 250-300g/m2 |

| Size Of Leaflet(LX W) | (110-260) X(100-180)mm |

| Specification Of Leaflet | 55-70g/m2 |

| Air Consumption | 10m3/h |

| Total Power | 380V 50HZ 1.5kw |

| Overall Dimension(LXHXW) | 3300 X1200 X 1700mm |

| Weight | 1500kg |

Shrink machine

| Power | 220V/380V 50/60HZ 3kw |

| Capcacity | 0-8packing/min |

| air source supply | 250L/min ,0.4-0.6Mpa |

| width/thickness of film | Max 590mm/ 0.03-0.25mm |

| Sealing length of sealing bar | 600mm |

| Max.packing size | 520*270*350mm |

| Min.packing size | 250*50*100mm |

| Dimension | 1160*1600*1930mm |

| Weight | 370kg |