Maintenance and maintenance of Rotary tablet press machine

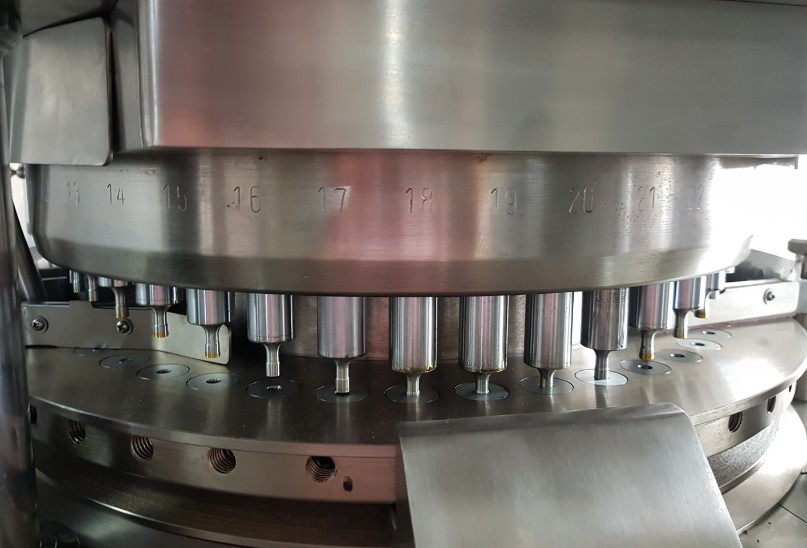

1. Check the parts regularly, once or twice a month. Check whether the worm gear, worm, bearing, pressure wheel, crankshaft, upper and lower rail guide and other moving parts are flexible and wear.

2. After use or shutdown, remove the remaining powder and brush the residual powder of all parts of the machine. If it is not used for a long time, the die must be removed, and the machine is wiped clean, the smooth surface of the machine is coated with anti-rust oil, and covered with a cloth cover;

3. the maintenance of the die should be placed in a special box, so that all the die into the oil, and to keep clean, do not make rust and bruise. it is best to customize the special box to each specification of a box, can avoid the use of wrong loading and help to master the loss and deficiency;

4. the use of the place should often clean, especially for medicine and edible tablet manufacturing should not have ash sand, flying dust;

5. electrical components should pay attention to maintenance, regular inspection, keep good running state. Cooling fan should be regularly cleaned with compressed air dust;

6. electrical components should pay attention to the working environment conditions (temperature, humidity), in a good environment, will prolong the service life of the components;

7. the maintenance of electrical components, should be carried out by professional and technical personnel, especially frequency converter should be more carefully engaged in, generally should be sent to professional manufacturers for maintenance;

8. Before insulation test on the electrical part of the machine, all the control lines of the main loop of the frequency converter must be removed to avoid damage to the frequency converter by insulation test. See the inverter operation manual for separate insulation test method.