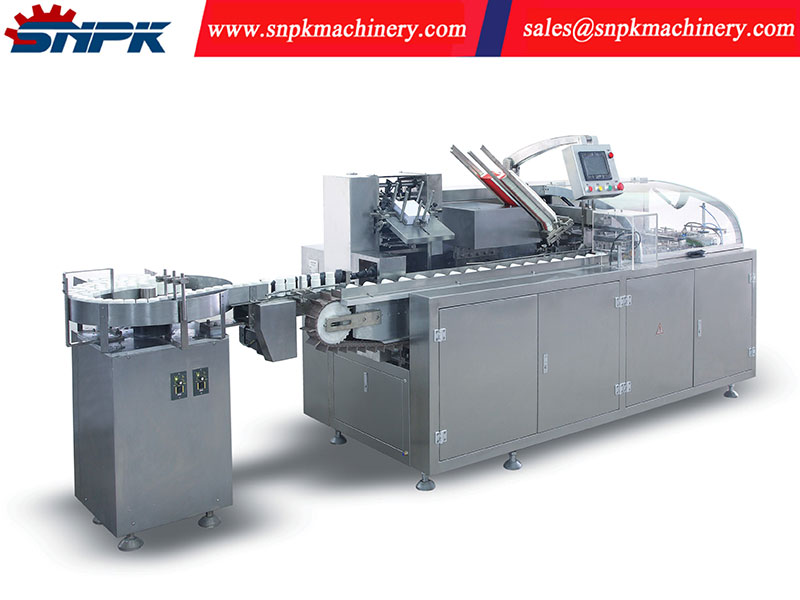

Fully automatic beer packing machine cartoning machine

Suitable for food industry, chemical industry, Commodity industry, pharmaceutical industry and other packaging.( soap,biscuit,hardware, bearing,candy,bread,INSTANT NOODLES ,fruit,COSMETICS,CAKES,brushtooth,ice cream,MEDICATED PLASTER,FACIAL MASK, CONDOM ,SEED ,DETERGENT POWDER, PREGNANCY TEST STICK,perfume,)

- category : cartoning machine

- email : delia@snpkmachinery.com

- email : tony@snpkmachinery.com

- email : sales@snpkmachinery.com

- mobile : +86-15958748873

- mobile : +86-15868796452

- whatsapp : +86-15958748873

- whatsapp : +86-15868796452

Application:

automatic cartoning machine for food suitable for pharmaceuticals, food, household chemicals, hardware and electrical industries for the packaging of blisters, bottles, vials, pillow packs, toothpaste, ect. It can fold leaflets, open cartons, insert the products and leaflets into cartons, emboss, tuck-in or hot-melt closures and automatically discharge cartons. The machine is equipped with a series of sensors and automatic protective devices to assure the machine runs safely and effectively. It can connect with the Blister Machine, Pillow Packaging Machine, Shrink-Wrapper, etc., to form a Packaging Line. It is the best choice for mass production.

Feature:

1. Japan Omron PLC control

2. Japan Omron inverter

3. Japan Omron touch screen

4. Automatic stop when machine is overload

5. Automatic reject lacking of package product and leaflet

6. Automatic trouble display, alarm and counting

7. Stable performance, operaion is easy

high-speed cartonning machine is newly designed by our company, and meets the GMP standard. There are features of high efficiency, stable properties and high capacity, etc. Many technologies, including the leaflet’s automatic folding & conveying, boxes forming and the post pushing unit, etc. meet the European & American standards. With the tidy appearance and the post continuous pushing structure, it’s convenient to operate and maintain. With the 4-indexing double-planet-wheel’s external-loop rotation, boxes can be opened, and there are twice pre-forming devices, so it’s ensures that boxes can be supported completely. The machine integrates the mechanism-optical-electric- pneumatic in one, and when it’s connected with other matched machines, it’s a complete packing line.

|

|

|

|

|

|

|

|

|

|

| Encasing Speed | 80-150box/min |

| Box Quality Requirement | 250-450g/m2 |

| (according to customer request) | |

| Box Dimension Range | (70-250)mmX(50-120)mmX(20-90)mm |

| can make special design as customer request | |

| Compressed Air Working Pressure | ≥0.6mpa |

| Air Consumption | 20m3/h |

| Power Supply | 380V 50Hz |

| Motor Power | 1.5KW |

| Machine Dimension | 3800X1350X1900mm |

| Machine Weight | 1500KGS |